Superconducting Resonator Fabrication facility

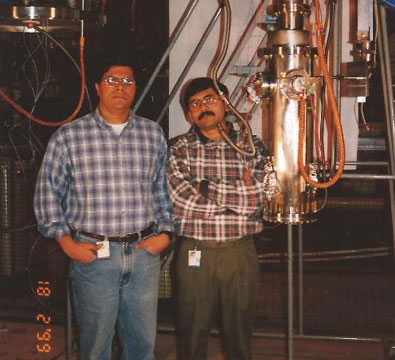

The prototype quarter-wave resonator (QWR) for the IUAC-Superconducting Linac (SC Linac) was designed and developed in collaboration with Argonne National Laboratory (ANL), USA. A batch of twelve QWRs for the first module of the linac was also fabricated at ANL. Resonator fabrication facilities were thereafter set up at IUAC for the in-house production of niobium resonators. In addition to the infrastructure set up at IUAC, a local vendor was also identified and his manpower was suitably trained to perform the various machining, forming, rolling, fitting, and fixture fabrication jobs associated with the niobium resonator production.

1. The Infrastructure

2. Resonator Fabrication

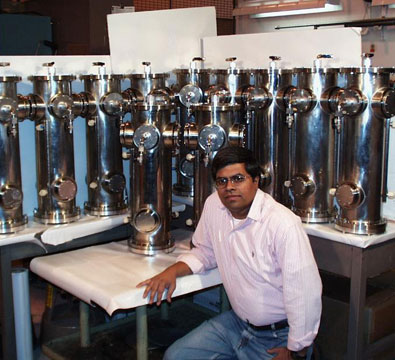

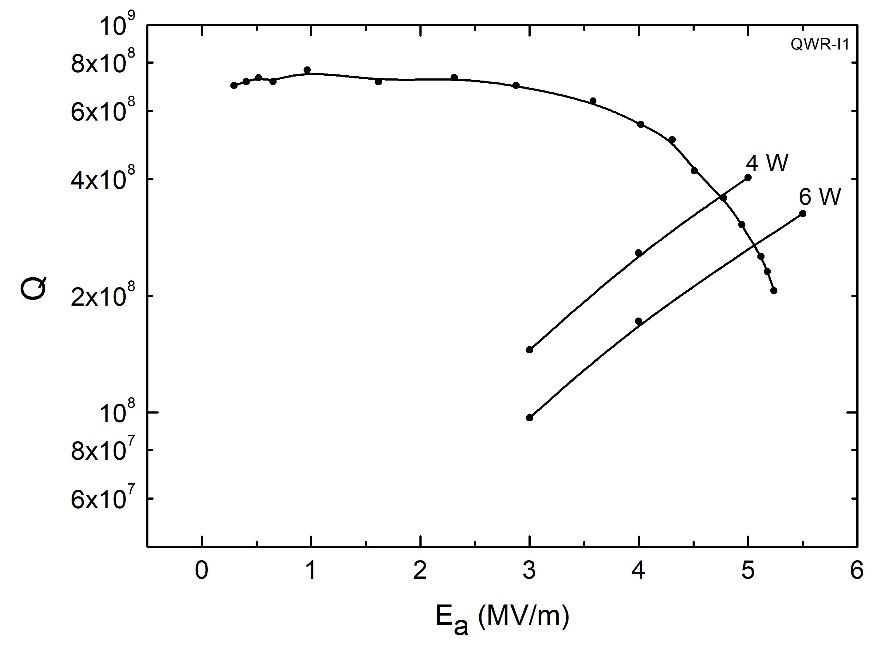

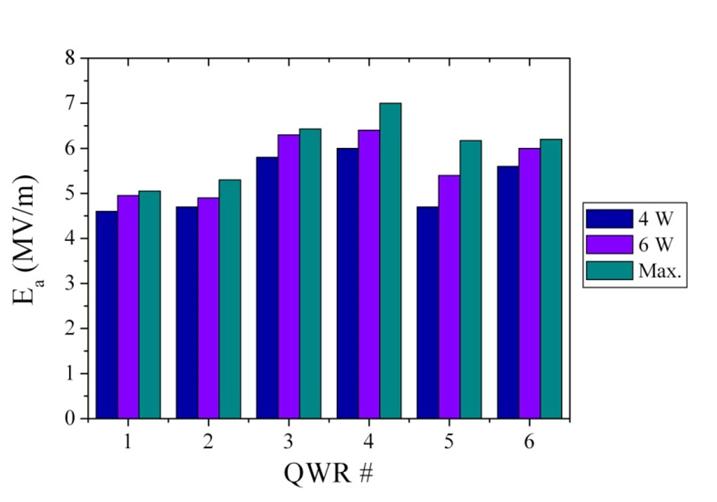

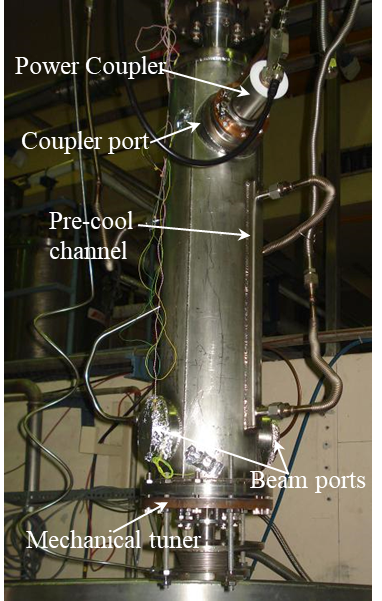

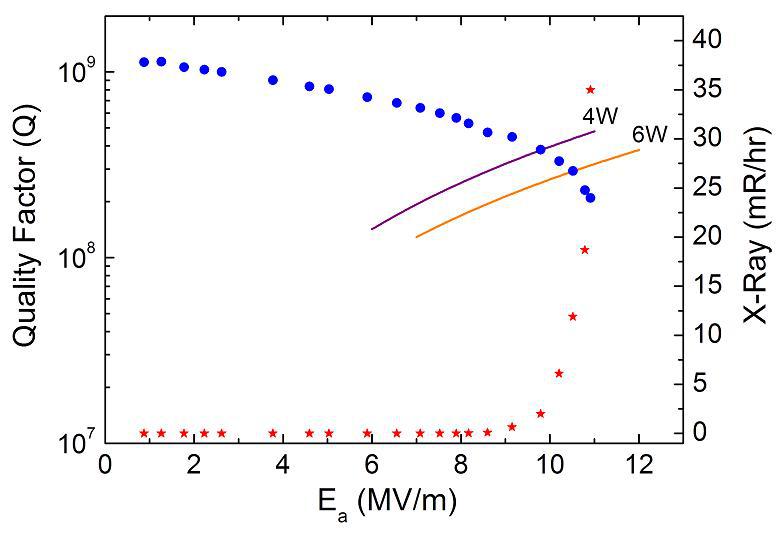

The first QWR in IUAC was built in 2003. In a cold test at 4.2K, it easily exceeded the nominal design goal of >4MV/m at 6W RF input power (link to picture and test result - figure 1). The first completely indigenous QWR for the SC Linac along with its mechanical tuner was successfully built-in 2004 (link to picture - figure 2). This was followed by the bulk production of fifteen QWRs and their mechanical tuners (link to figure 3) for the second and third linac modules. These cavities are all installed in the linac and have been accelerating beam regularly for the past several years (link to test results - figure 4).

b) The low beta resonator:

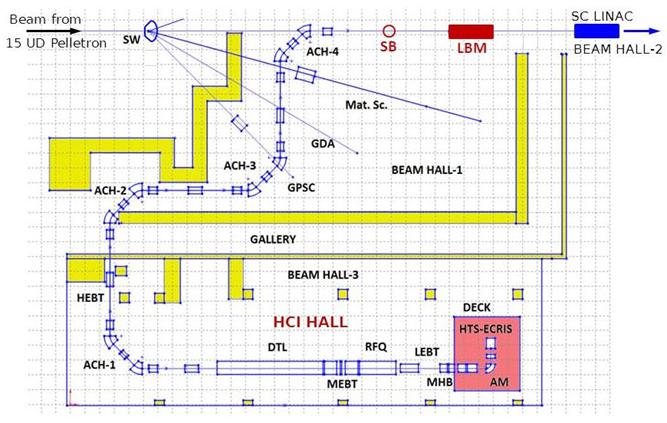

A prototype β=0.05 resonator operating at 97 MHz frequency has been designed and developed using the SRF infrastructure at IUAC. This resonator will be used in the proposed low beta module (link to the layout of HCI beamline figure 5) in the upcoming high current injector (HCI) at IUAC. The low beta module will serve to better match the ion velocity from the HCI before injection into the SC Linac…. (read more links with resonator design details given in the next paragraph).

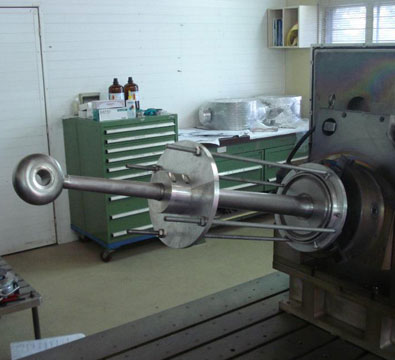

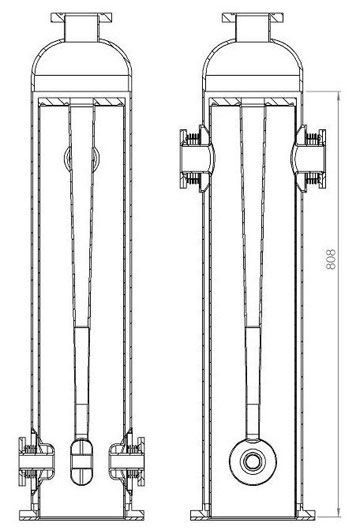

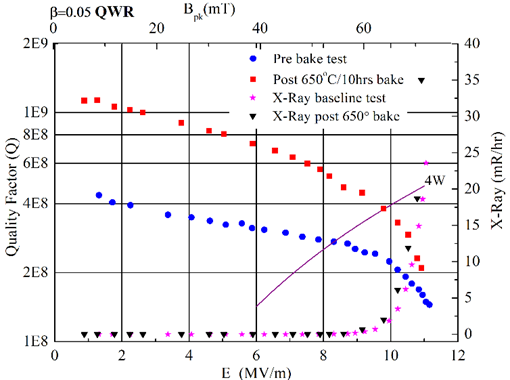

The electromagnetic design of the low beta resonator is an improvement over the QWR design. It has a tapered central conductor with a small donut-shaped drift tube at the open end (link to schematic and picture in figure 6)., Unlike the QWR, the capacitive loading of the transmission line is much less in the new design, resulting in lower stored energy and hence an easier phase control of the cavity. The peak surface magnetic field of the resonator has also been reduced to less than half of its value in the SC Linac-QWR (link to table 1). This allows the cavity to go to much higher accelerating gradients (link to test results in figure 7) before the peak magnetic field on the RF surface exceeds the critical magnetic field for niobium, causing a quench. Its mechanical design is quite similar to the QWR in that the niobium resonator is jacketed by a stainless-steel helium vessel and is bath cooled with liquid helium to 4.2K. Transitions from SS to niobium are once again provided through Nb-SS explosively bonded flanges like in the QWR. Care has been taken during the mechanical design to keep the dimensions of the low beta resonator similar to those of the QWR wherever possible for the ease of fabrication as well as to benefit in the low beta cryomodule design from the experience gathered with the present linac cryomodules.

| Operating frequency | 97 MHz |

| Optimum beta (v/c) | 0.05 |

| Stored energy @ 1 MV/m accelerating field | 0.026 J/(MV/m)2 |

| Peak surface magnetic field @ 1 MV/m accelerating field | 6.4 mT |

| Peak surface electric field @ 1 MV/m accelerating field | 3.45 MV/m |

| Geometric factor (QRs) | 16.1 Ω |

| Shunt Impedance (RSh/Q) | 650 Ω |

| Effective accelerating length (Leff) | 104 mm |

| Operating Temperature | 4.2 K |

| Design value of operating accelerating field (Ea) | 6 MV/m |

| Quality factor @ (Ea) | >3X108 |

Table 1: Electromagnetic parameters of the low beta resonator

3. Collaborations

Besides the development of QWRs for the superconducting linac and the design and development of the prototype low beta resonator, the SRF infrastructure at IUAC has been extensively used for many national and international collaborative projects…. (read more link)

a) Single Spoke Resonators (SSR1):

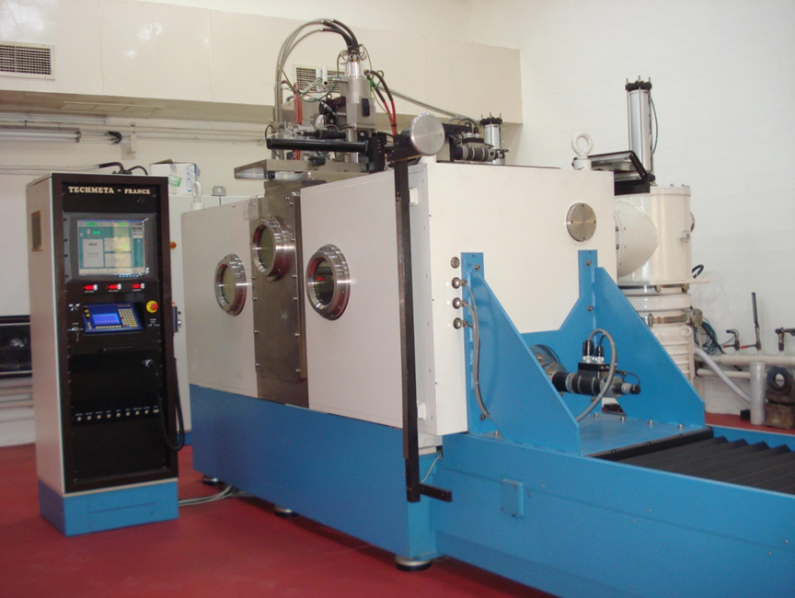

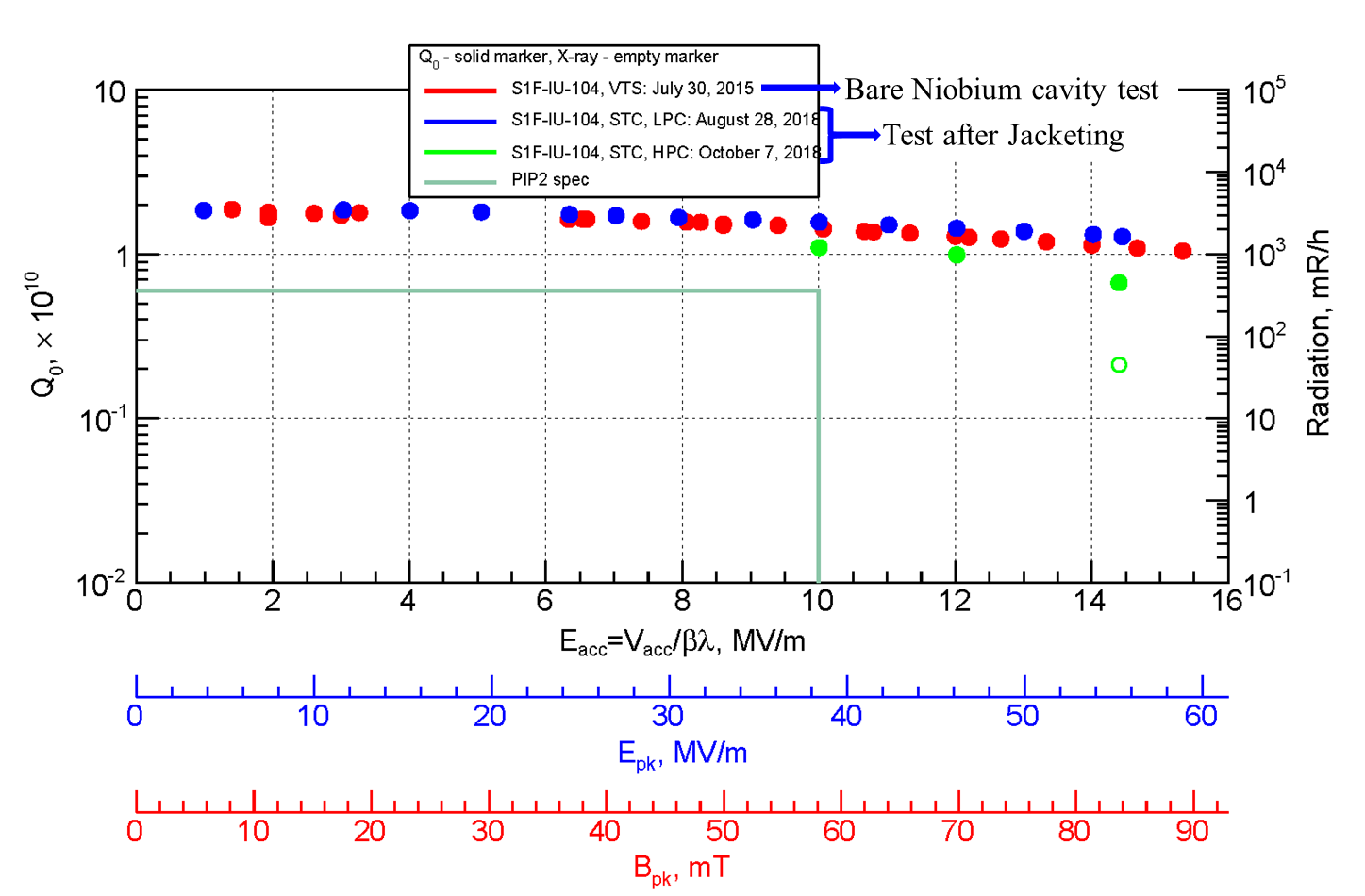

IUAC has successfully fabricated two nos. of bare niobium SSR1 Single Spoke Resonators for use in the PIP-II project at Fermi National Accelerator Laboratory (FNAL), USA… (read more link). This project was carried out under MoU between the two labs wherein FNAL provided the design drawings for the resonator, the required niobium material, and the necessary funds for the construction and development. The work was carried out by IUAC on a best effort basis using the SRF infrastructure and the facilities available with the same vendor who had worked during the QWR fabrication. All forming, rolling, machining, and fabrication of various fixtures was performed at the vendor’s site while the surface treatment of the resonator parts & sub-assemblies and their electron beam welding was carried out at IUAC (link to figure 8). Both the resonators (link to picture of completed SSR 1 resonators in figure 9) were shipped to FNAL in March 2015, where they were given another round of surface treatment before the cold test. Both the cavities were able to meet the PIP-II design goal of Q0 ≥ 5X109 @ 10 MV/m @ 2K. Subsequently, the better of the two cavities was jacketed with a stainless-steel helium vessel. The jacketing work was carried out at Bhabha Atomic Research Centre (BARC), Mumbai in collaboration with IUAC. The cavity was then shipped back to FNAL where another cold test was performed after suitable surface processing. The result of the second cold test is among the best obtained in this class of resonators built anywhere (link to the test results in figure 10). The results were a clear indication that the fabrication and processing techniques followed at IUAC are at par with the international standards. The cavity has since been installed in the PIP-II Injector Test Experiment (PIP-2IT) beamline for beam acceleration.

b) Development of single-cell and multi-cell elliptical cavities in collaboration with RRCAT, Indore:

This was a collaborative project between IUAC and Raja Ramanna Centre for Advanced Technology (RRCAT), Indore with an aim to develop TESLA type single cell and multi-cell superconducting niobium cavities. The role of IUAC was to share its expertise in fabrication of niobium cavities, designing of various fixtures for machining and electron beam welding, development of welding parameters and subsequently perform electron beam welding of the niobium cavities… (read more link)

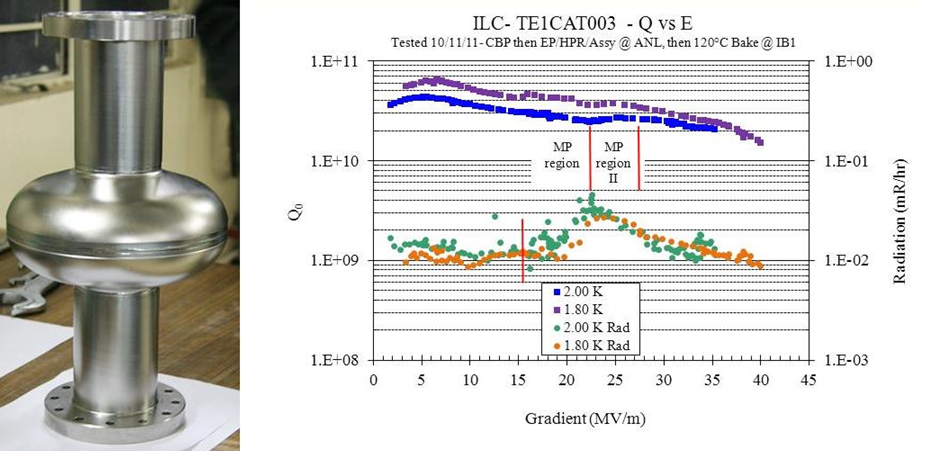

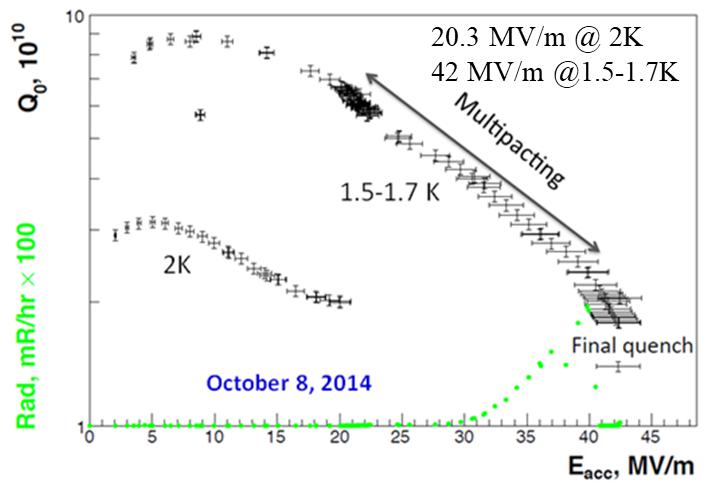

- 1.3 GHz TESLA-type single Cell and multi-cell Elliptical Cavities: A total of four single cell cavities were developed. These were processed and tested at FNAL. All the four cavities performed very well. One of the cavities could achieve a Q0 of 1.5 X1010 @ 40 MV/m @ 1.8 K (link to cavity picture and Q curve in figure 11). No X-Ray emission was observed at the highest gradient. The result once again indicated that the weld preparation procedure and the quality of the electron beam welds obtained at IUAC is comparable with international standards. Encouraged with the single cell cavity results, a five-cell elliptical cavity was later welded using the EBW facility at IUAC. This was the largest cavity size that could be accommodated within the welding chamber of the EBW machine. The cavity achieved 42 MV/m at 1.7K. (link to cavity picture and test results in figure 12).

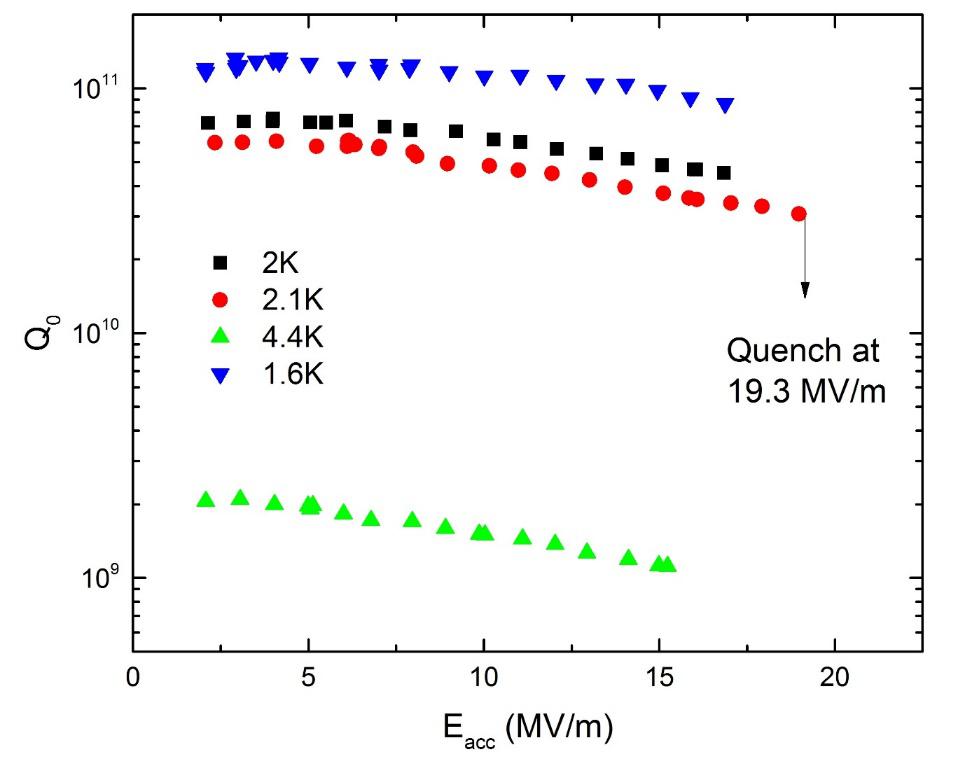

- 650 MHz, β=0.9 Single Cell Elliptical Cavity: A 650 MHz single cell cavity was also fabricated under the same collaboration. This was also processed and tested at FNAL. At 2.1K, it achieved a Q0 of 3 X1010 at 19.3 MV/m exceeding the design goal, before quenching. (link to cavity picture and test results in figure 13)

c) Development of 650 MHz, β=0.6 Single Cell Low Beta Elliptical Cavities in collaboration with VECC, Kolkata:

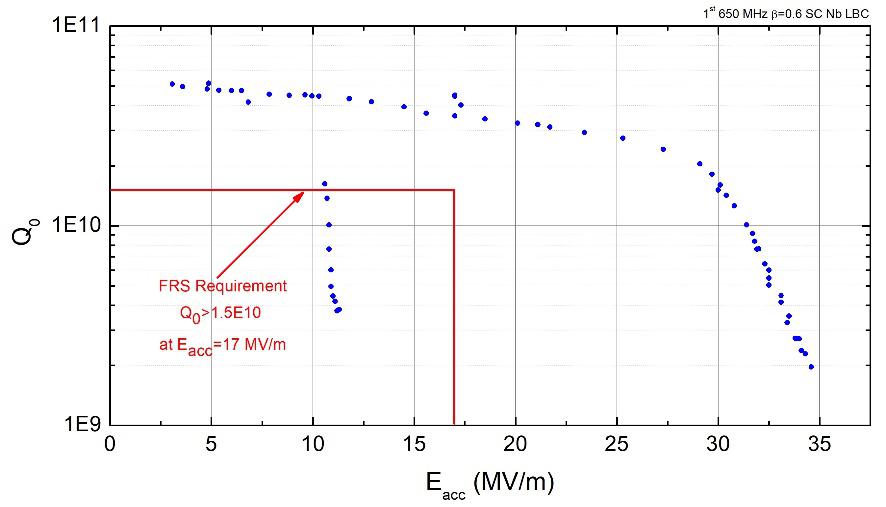

In this collaboration also the various cavity components have been fabricated by VECC by benefitting from the expertise shared by IUAC…(read more link). In addition, the development of various fixtures, including the welding fixtures have been developed in consultation with the IUAC team. The weld parameter development, preparation of the weld joints and the actual electron beam welding of the cavity components was performed at IUAC. Two single-cell cavities have been fabricated. One of them has been processed and tested at Fermi Lab. It has achieved an accelerating gradient of 34.5 MV/m without quenching, which is a world record in this class of cavities (link to a picture of the cavity and test results in Figure 14). The second cavity has been completed and is awaiting final processing and testing.

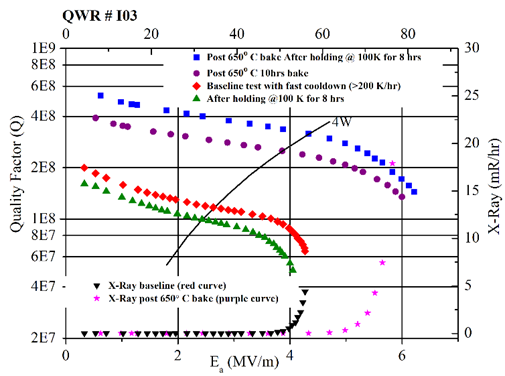

4. Studies on the effect of High Temperature Heat Treatment on QWR Performance

Apart from the regular activities related to niobium resonator fabrication and testing, the SRF infrastructure, especially the high vacuum furnace facility and the surface preparation laboratory, has been extensively used to perform studies on the effect of high temperature heat treatment on jacketed QWRs…. (read more link). One of the indigenously fabricated QWR and the prototype low beta resonator were chosen for the study. Both resonators were given the standard surface treatment and cold tests were performed to establish a baseline performance result. Thereafter, both of them were heat treated @ 650°C for 8 hours in the high vacuum furnace and tested again after suitable surface treatment. A substantial improvement (factor of ~2.5) was observed in both the resonators (link to Q-E curves shown in figure 15). These encouraging results on resonators of two different designs have prompted the inclusion of this technique in the standard surface treatment recipe followed at IUAC.

Group Members

Shri. Abhishek Rai (Scientist ‘F’)

Shri. S. S. K. Sonti (Junior Engineer ‘F’)

Shri. K. K. Mistri (Junior Engineer ‘F’)

6. Publications – A glimpse

- Improvement of Accelerating Gradients in Niobium Quarter Wave Resonators - A. Rai, P. N. Potukuchi, P. Patra, G. K. Chaudhari, S. S. K. Sonti, J. Karmakar, B. Karmakar, A. Sharma, D. S. Mathuria, A. Pandey, R. N. Dutt, B. K. Sahu, S. Ghosh and D. Kanjilal, Supercond. Sci. Technol. 32 (2019) 095003.

- Investigation of High-Temperature Baking of Niobium Quarter Wave Resonators - A. Rai, P.N. Prakash, S. S. K. Sonti, P. Patra, K.K. Mistri and D. Kanjilal, proceedings of 18th International Conference on RF Superconductivity (SRF), July 17-21, 2017, Lanzhou, China, page 598.

- Test result of 650 MHz, beta 0.61, single-cell niobium cavity - Sudeshna Seth, Sumit Som, Surajit Ghosh, Pranab Bhattacharyya, Aditya Mandal, Sundeep Ghosh, Anjan Dutta Gupta, P. N. Prakash, Kishore Kumar Mistri, Thomas H. Nicol, Allan Rowe, Anna Grassellino, Timergali N. Khabiboulline, Dmitri A. Sergatskov, Oleksandr Stepanovych Melnychuk, Shekhar Mishra, Michael Kelly, Thomas Reid, Proc. of 18th International Conference on RF Superconductivity SRF2017, 17-21 July 2017, Lanzhou, China, p553.

- Cold Tests of SSR1 Resonators Manufactured by IUAC for the Fermilab PIP-II Project - L. Ristori, A. Grassellino, O. Melnychuk, A. Sukhanov, D.A. Sergatskov, P.N. Potukuchi, K. K. Mistri, A. Rai, J. Sacharias, S.S.K. Sonti, proceedings of 17th International Conference on RF Superconductivity (SRF), September 13-18, 2015, Whistler, BC, Canada, page 750.

- Design of 650 MHz, beta=0.61, 5-cell SRF cavity and development of single-cell niobium cavity - Sudeshna Seth……. P.N. Prakash, Proc. of DAE-BRNS Indian Particle Accelerator Conference - InPAC-2015, December 21-24, 2015, TIFR, Mumbai, p383.

- Electron beam welding of SSR1 resonators at IUAC – K.K. Mistri and P.N. Prakash, Proc. of DAE-BRNS Indian Particle Accelerator Conference - InPAC-2015, December 21-24, 2015, TIFR, Mumbai, p804

- Superconducting radio frequency cavities: design, development and results – P.N. Prakash, Proc. of DAE-BRNS Indian Particle Accelerator Conference - InPAC-2013, Nov. 19-22, 2013, VECC, Kolkata, p30.

- Development of 1.3 GHz five cell SCRF cavity – T Maura, A. Yedle, M. Bagre, A. Yadav, A. Puntambekar, R.S. Choudhary, R.S. Sandha, G.V. Kane, J. Dwivedi, A. Mahawar, p. Mohania, K.A.P. Singh, V. Rajput, P. Shrivastava, S. Sharma, R.K. Gupta, G. Mundra, S.C. Joshi, K.K. Mistri and P.N. Prakash, Proc. of DAE-BRNS Indian Particle Accelerator Conference - InPAC-2013, Nov. 19-22, 2013, VECC, Kolkata, p525.

- Development of 650 MHz (β=0.9) single-cell SCRF cavity – M. Bagre, V. Jain, A. Yedle, T. Maurya, A. Yadav, A. Puntambekar, S.G. Goswami, R.S. Choudhary, R.S. Sandha, J. Dwivedi, G.V. Kane, A. Mahawar, P. Mohania, P. Shrivastava, S. Sharma, R. Gupta, S.D. Sharma, S.C. Joshi, K.K. Mistri and P.N. Prakash, Proc. of DAE-BRNS Indian Particle Accelerator Conference - InPAC-2013, Nov. 19-22, 2013, VECC, Kolkata, p401.

- Design of a superconducting low beta niobium resonator - Prakash N. Potukuchi and Amit Roy, PRAMANA Journal of Physics, Vol. 78, No. 4, April 2012, pp. 565-584.

- Superconducting low beta niobium resonator for heavy ions - Prakash N. Potukuchi et al., Proc. of 26th International Linear Accelerator Conference – LINAC2012, Sept. 9-14, Tel Aviv, Israel, p588.

- Superconducting properties of niobium after electron beam welding – Prakash N. Potukuchi, L.S. Sharath Chandra, M.K. Chattopadhyay, D. Kanjilal, Amit Roy and S.B. Roy, Phys. Rev. ST – AB 14, 122001 (2011).

- Development of 1.3 GHz prototype niobium single-cell superconducting cavity under IIFC collaboration – A. Puntambekar, M. Bagre, V. Jain, R. K. Gupta, R. S. Sandha, G. V. Kane, S. D. Sharma, J. Dwivedi, P. Shrivastava, S. C. Joshi, P. D. Gupta, V. C. Sahni, P. N. Potukuchi, J. Sacharias, K. K. Mistri, D. Kanjilal, T. Khabiboulline, A. Rowe, C. Cooper, J. Ozelis, M. Foley, S. Mishra, Proc. of 2011 Particle Accelerator Conference PAC’11, March 28-April 01, 2011, Brookhaven National Laboratory, New York, USA, p871.

- Single cell SCRF cavity development in India – A. Puntambekar, J. Dwivedi, P. Shrivastava, S. C. Joshi, G. Mundra, P. D. Gupta, P. N. Potukuchi, T. Khabiboulline, A. Rowe, C. Cooper, J. Ozelis, M. Foley, S. Mishra, G. Wu, Proc. of 15th International Conference on RF Superconductivity SRF2011, July 25-29, 2011, Chicago, USA, p659.

- SRF Activities at IUAC – Prakash N. Potukuchi, Proc. of DAE-BRNS Indian Particle Accelerator Conference InPAC2011, Feb. 15-18, 2011, Inter-University Accelerator Centre, New Delhi.

- Superconducting low beta resonator for the high current injector at IUAC – Prakash N. Potukuchi and Amit Roy, Proc. of DAE-BRNS Indian Particle Accelerator Conference InPAC2011, Feb. 15-18, 2011, Inter-University Accelerator Centre, New Delhi.

- Superconducting cavity tests at IUAC: Lessons learnt and subsequent improvements – A. Rai, S. Ghosh, P. Patra, G.K. Chaudhari, A. Pandey, B.K. Sahu, D.S. Mathuria, R.N. Dutt, J. Antony, R. Kumar, S.S.K. Sonti, K.K. Mistri, J. Zacharias, P.N. Prakash, D. Kanjilal and A. Roy, Proc. of DAE-BRNS Indian Particle Accelerator Conference InPAC2011, Feb. 15-18, 2011, Inter-University Accelerator Centre, New Delhi.

- Indian cavity fabrication facility and test results – P.N. Potukuchi, Proc. of 14th International Conference on RF Superconductivity SRF 2009, Sept. 20-25, Berlin, Germany, p502.

- Fabrication of superconducting niobium resonators at IUAC – P.N. Potukuchi, K.K. Mistri, S.S.K. Sonti, J. Zacharias, A. Rai, D. Kanjilal and A. Roy, Proc. of 11th International Conference on Heavy Ion Accelerator Technology, HIAT 09, 8-12 June 2009, Venice, Italy, p266.

- Superconducting Niobium Resonator Fabrication at IUAC - P.N. Prakash, K.K. Mistri, S.S.K. Sonti, J. Zacharias, A. Rai, D. Kanjilal and A. Roy, Proceedings of InPAC-2009, Feb 10-13, 2009, RRCAT, Indore.

- Superconducting niobium resonator fabrication and testing at IUAC – P.N. Prakash, S.S.K. Sonti, K.K. Mistri, J. Zacharias, D. Kanjilal and A. Roy, Proc. of Asian Particle Accelerator Conference APAC-2007, Jan. 29-Feb. 2, 2007, Raja Ramanna Centre for Advanced Technology, Indore, p500.

- Production of superconducting Nb QWRs at IUAC – S.S.K. Sonti, K.K. Mistri, J. Zacharias, P.N. Prakash, D. Kanjilal and A. Roy, proc. of DAE-BRNS Indian Particle Accelerator Conference InPAC-2006, Nov. 1-4, 2006, Bhabha Atomic Research Centre, Mumbai, p139.

- Fabrication of superconducting niobium cavities at Nuclear Science Centre – P.N. Prakash, J. Zacharias, K.K. Mistri, S.S.K. Sonti and A. Roy, Proc. of Asian Particle Accelerator Conference APAC 2004, March 22-26, 2004, Gyeongju, Korea, p684.

- Surface preparation of niobium superconducting QWR – R. Mehta, P.N. Prakash, G.K Chaudhari, S. Ghosh, S.S.K. Sonti, A, Rai, D.S. Mathuria, J. Antony, K.K. Mistri and A. Roy, Proc. of Indian Particle Accelerator Conference InPAC 2005, March 1-5, 2005, Variable Energy Cyclotron Centre, Kolkata, p529

- Superconducting resonator fabrication facility (SuRFF) at Nuclear Science Centre – P.N. Prakash, J. Zacharias, S. Ghosh, R. Mehta and A. Roy, Proc. of Symposium on Electron Beam Technology and Applications (SEBTA 2000), Nov. 22-24, 2000, Bhabha Atomic Research Centre, Mumbai, p143.

Media Gallery

Photos of various niobium cavities/components etc. and visits by eminent national and international persons.