Thin Film and Target Development Laboratory

About The Laboratory

This laboratory is one of the user support laboratories of IUAC which provides facilities and necessary help to the user community for the preparation of thin films and targets required to perform experiments using the accelerator facilities in the areas of Nuclear Physics, Atomic Physics, and Materials Science. More than 100 thin films and targets are prepared per year in this laboratory. Along with the preparation of targets, the laboratory also prepares 5 microgram/sq.cm thick, free-standing carbon foils used as a stripper for the 15UD Pelletron accelerator. Approximately 600-800 stripper foils are used in the Pelletron in a year. This laboratory provides the Transmission Electron Microscope (TEM) Facility.

Thin Film/Target Preparation Facilities

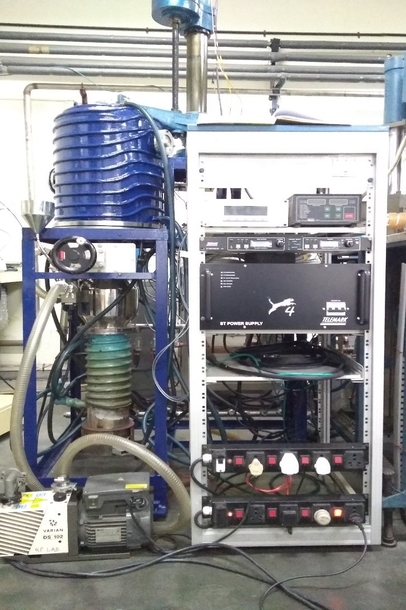

Evaporator-I

Features

- Resistive heating arrangement.

- A single pocket electron beam gun and 4kW power supply.

- Quartz crystal thickness monitor.

- Pumped by a diffusion pump with liquid nitrogen trap.

- Base pressure ~10-7 mbar.

Evaporator-II

Features

- A 4-pocket electron beam gun and 6kW power supply.

- Quartz crystal thickness monitor within an accuracy of 1 Angstrom.

- Pumped by a Turbo-Molecular pump with Scroll pump roughing.

- Base pressure ~10-7 mbar.

Evaporator-III

Features

- A 6-pocket electron beam gun and 6kW power supply.

- Quartz crystal thickness monitor within an accuracy of 1 Angstrom.

- Pumped by a Turbo-Molecular pump with Scroll pump roughing.

- Base pressure ~10-7 mbar.

Evaporator-IV

Features

- Resistive heating arrangement.

- A single pocket electron beam gun and 6kW power supply.

- D-type front opening chamber for easy cleaning.

- Quartz crystal thickness monitor within an accuracy of 1 Angstrom.

- Pumped by a Turbo-Molecular pump with Scroll pump roughing.

- Base pressure ~10-7 mbar.

Atom-beam Sputtering Setup

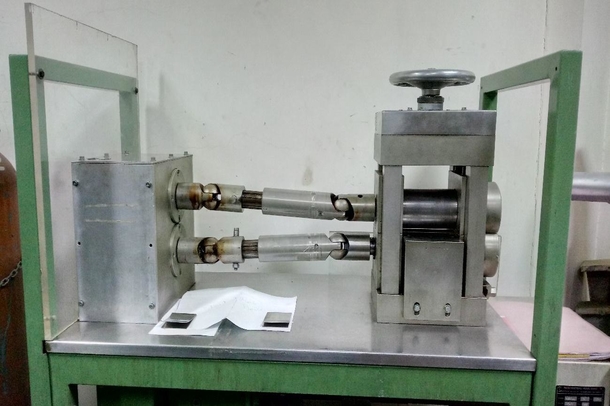

Rolling Machine

- This machine is used to prepare thin foils by cold rolling method.

- The material to be rolled is placed between two mirror polished stainless steel plates and rolled through especially hardened rollers. The gap between the rollers is reduced gradually to achieve thinner foils.

- Foils of ductile metals of thickness of the order of 1 mg/cm2 can be prepared by this method.

- Very efficient method, no loss of expensive materials.

Precision Thin Film Thickness Measurement Facilities

The thickness measured by quartz crystal thickness monitor or by weighing method may not be very accurate. For the absolute thickness measurement of thin the following methods are used.

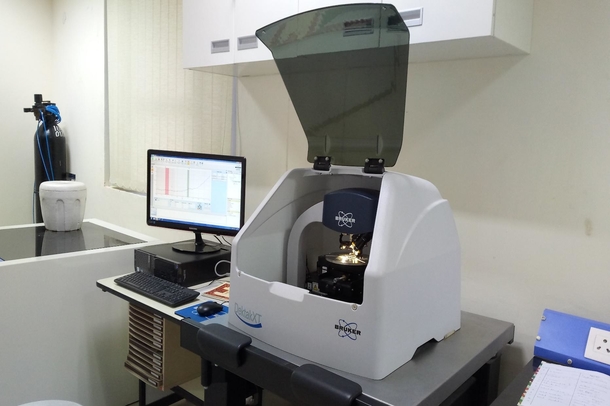

Stylus Surface Profiler

Features

- To measure the thickness of the thin films deposited on some substrate.

- Requires a step to be present at the edge of thin film.

- Make/Model: Bruker - Stylus Profiler - DektakXT

Alpha Energy Loss Target Thickness Measurement Setup

For the thickness measurement of thin free-standing foils, the following method is used. The thickness of the foil is determined by measuring the energy lost by the particles while passing through it and comparing it with the theoretical value.

The steps followed are:

- 5.486 MeV alpha particles from Am-241 radioactive source are allowed to pass through the foil.

- The particles are detected by a solid state surface barrier detector.

- The spectrum is recorded in a multi-channel analyzer (MCA).

- The multi-channel analyzer is calibrated to measure energy.

- The specific energy loss of the 5.486 MeV alpha particle in the foil material determined from the available theoretical value.

Using micro balance:

Areal density or mass thickness (wt./area) of free-standing foils (especially rolled foils) are evaluated by measuring the weight of foils using a precision micro-balance and dividing by the area of the foils. Knowing the density of the materials can be converted to the thickness of the foils.

Other Facilities

Micro Balance

Features

- Useful to measure the weight with an accuracy of 10 microgram.

- Used to measure weight of isotopic material before evaporation and after evaporation to evaluate material consumed during evaporation.

- Required to measure areal density or mass thickness (wt./area) during target preparation using cold rolling technique.

Pellet Making Press

Features

- Half ton press is used to make pellets.

- 6 mm pellet can be made by using proper die. It can be used for the preparation of targets in pelletized form.

- It is also used for compacting powder materials before evaporation.

Tube Furnace

Features

- Annealing at temperature up to 900˚C.

- A 8-ramp 8-dwell multi programmable controller.

- Annealing in controlled atmosphere inside quartz tube.

Vertically downwards laminar flow with chemical exhaust and Laminar flow clean air system

Features

- For the cleaning and chemical treatment of substrates before thin-film growth.

- Creates clean environment by flowing filtered air on the work table. There is also chemical exhaust, which drives chemical fumes out of the laboratory.

Electrical and Optical Measurement

Releasing Agent Coating System and Automated Target Floating System

Features

- A modified spin coating system dedicated to releasing agent coating applications.

- A modified dip-coating system dedicated to automated target floating applications.

Transmission Electron Microscope (TEM) Facility

TEM Specimen Preparation

Features

- This lab is equipped with Hot Plate, Traditional Lapping/Grinding Tools, Dimple Grinder, Diamond Wire Saw and Precision Ion Polishing System (PIPS) for TEM sample preparation.

- TEM, Cross-sectional TEM (XTEM) and Powder samples on TEM Grids can be prepared here for TEM characterization.

TEM Facility

Features

- Manufacturer/Model: JEOL/JEM-F200

- Electron Gun: Thermal Electron Field Emission Electron Gun (TFEG)

- TEM Imaging Camera: OneView CMOS Camera (4k × 4k pixels)

- Scanning TEM Imaging: High Angle Annular Dark Field (HAADF)

- Energy Dispersive X-ray Spectroscopy (EDS): JEOL windowless Silicon Drift Detector