About Indian National Gamma Array

The concept of a national facility for γ-spectroscopy took shape in early 2000 when a formal agreement between the various institutions (TIFR ![]() , BARC

, BARC ![]() , SINP

, SINP ![]() , VECC

, VECC ![]() , UGC-DAE CSR and

, UGC-DAE CSR and ![]() IUAC

IUAC ![]() ) was achieved for pooling the available resources. It was conceived that an Indian National Gamma Array consisting of Compton-suppressed Clover detectors with nearly 4π coverage would be set up as a national facility.

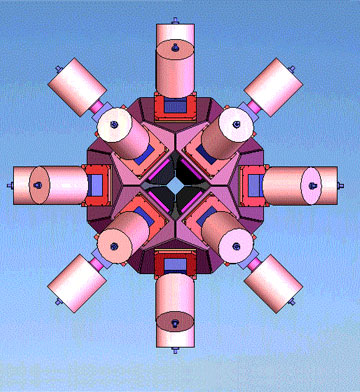

) was achieved for pooling the available resources. It was conceived that an Indian National Gamma Array consisting of Compton-suppressed Clover detectors with nearly 4π coverage would be set up as a national facility.

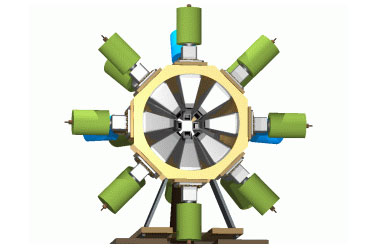

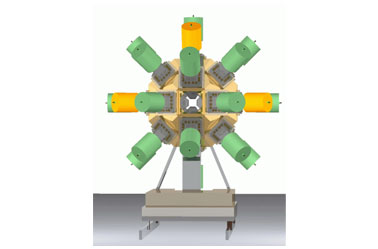

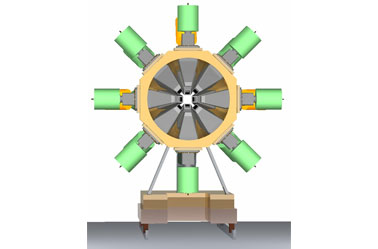

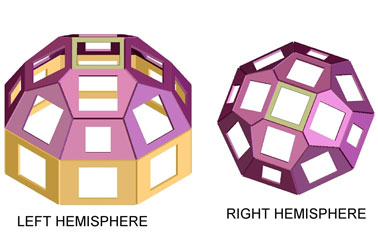

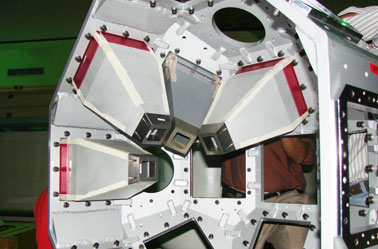

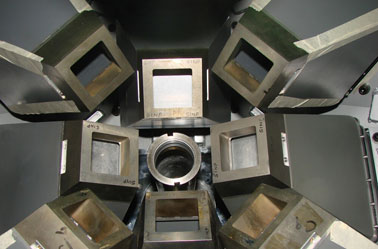

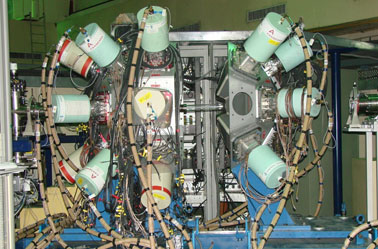

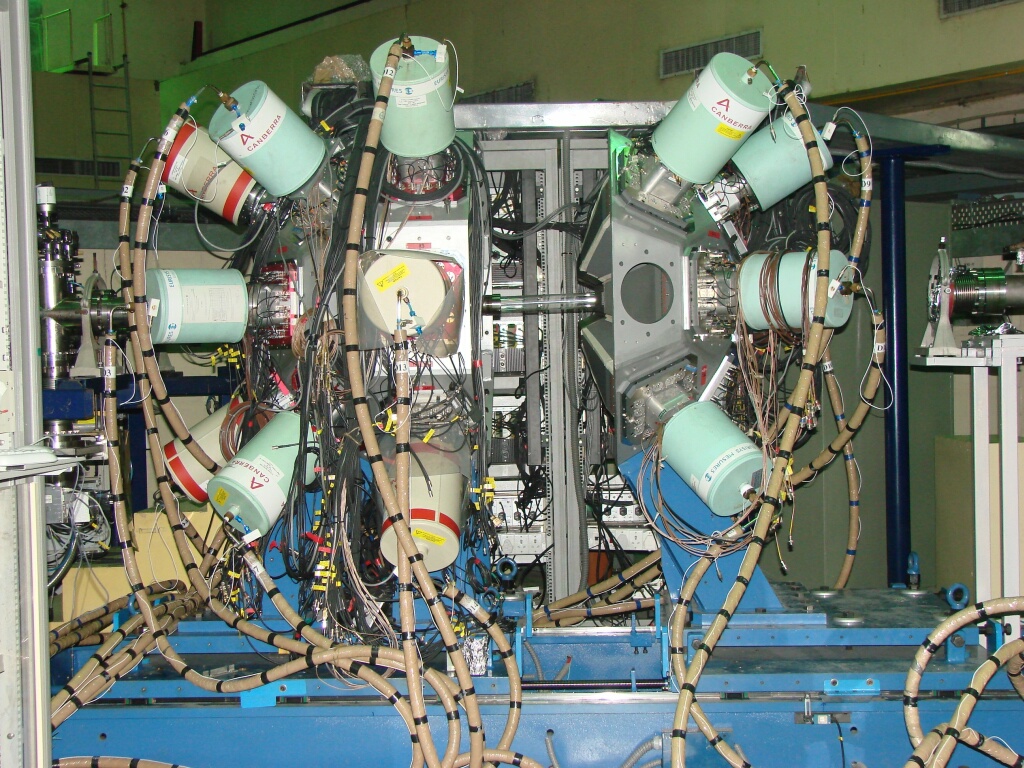

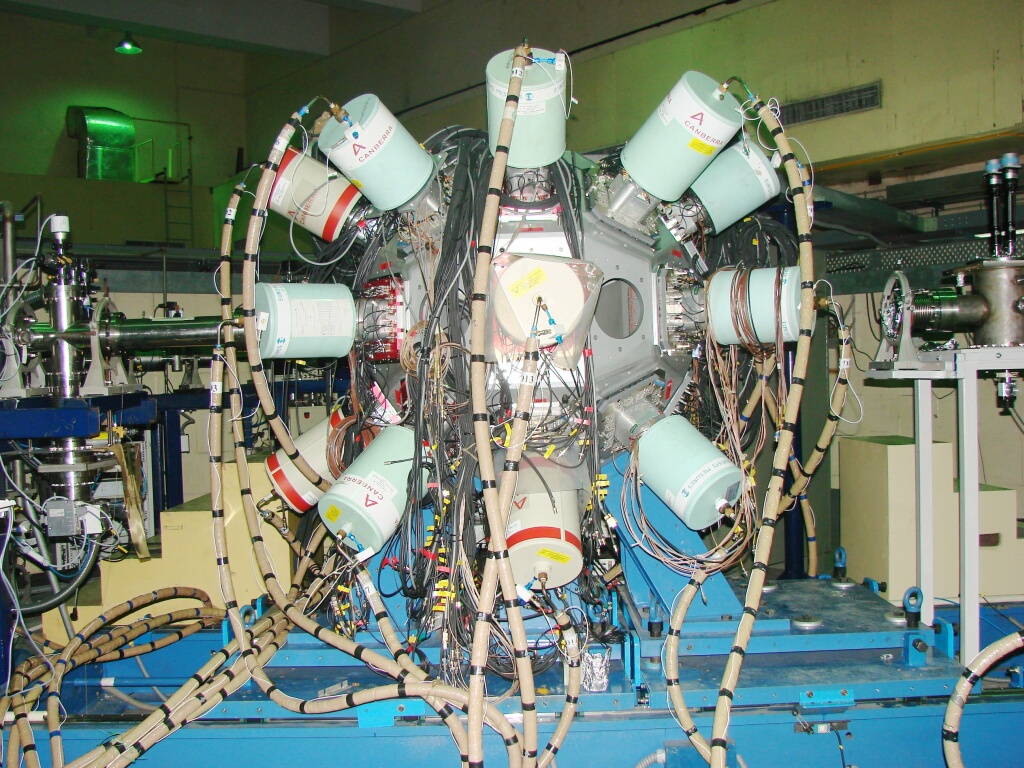

This facility would be rotated among the three accelerator laboratories in India with a minimum stay of one year at one place. Major funding for this project has been received from the Department of Science and Technology, Government of India. The Clover detectors that were available with the institutions were designed to be operated at a distance of ∼ 24 cm from the target with the accompanying anti-Compton shields subtending an angle of 30o at the target. As a result, a maximum of 24 Clover detectors could be accommodated in 4π geometry. The total coverage by Ge crystals is about 25% of 4π, corresponding to a total photopeak efficiency of ∼ 5%. Such a system would be optimized for collecting data at triples (γ-γ-γ) or at higher fold. Three campaigns with a smaller number of Clover detectors were carried out in 2001, 2003 and 2005 at TIFR, IUAC and VECC, respectively, with existing infrastructure.

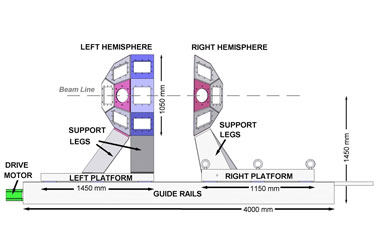

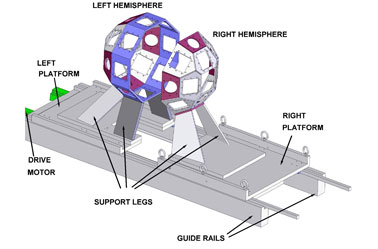

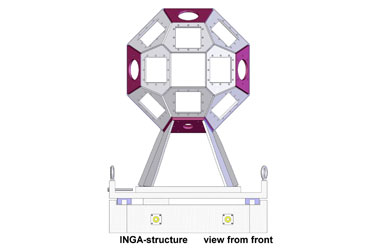

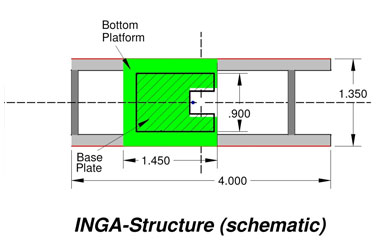

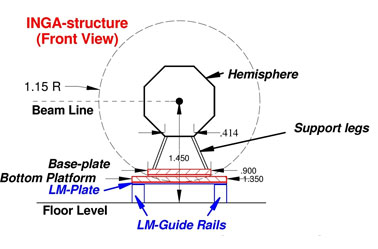

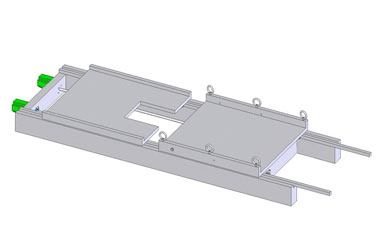

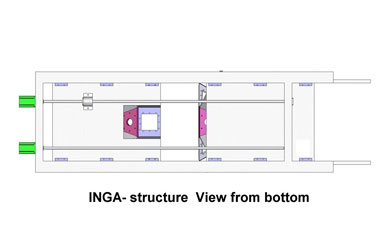

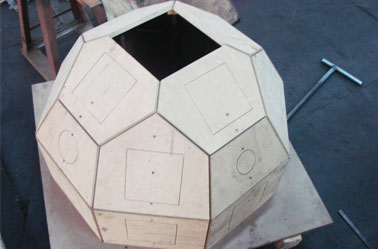

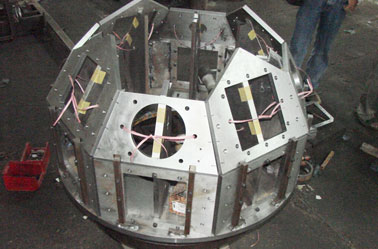

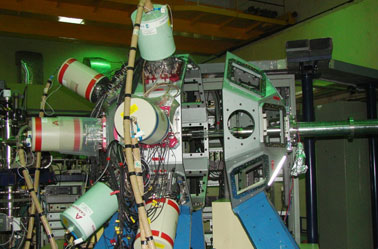

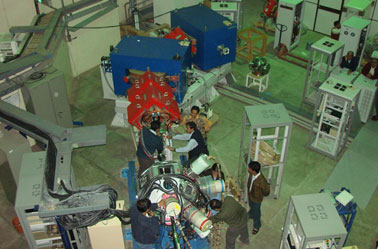

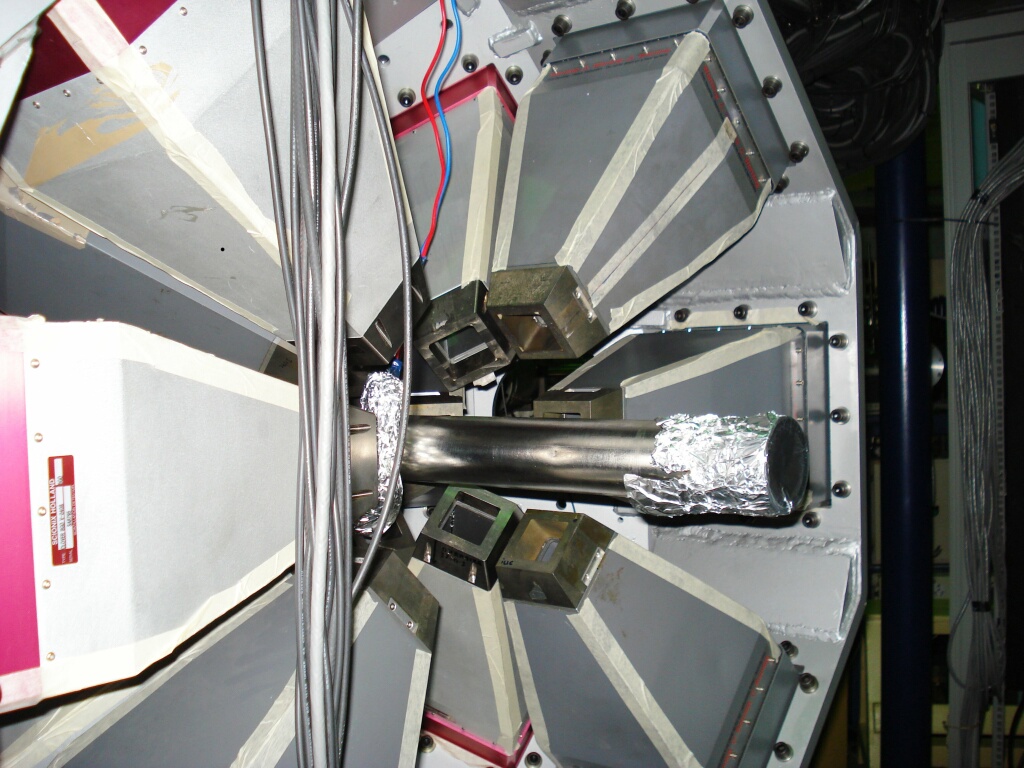

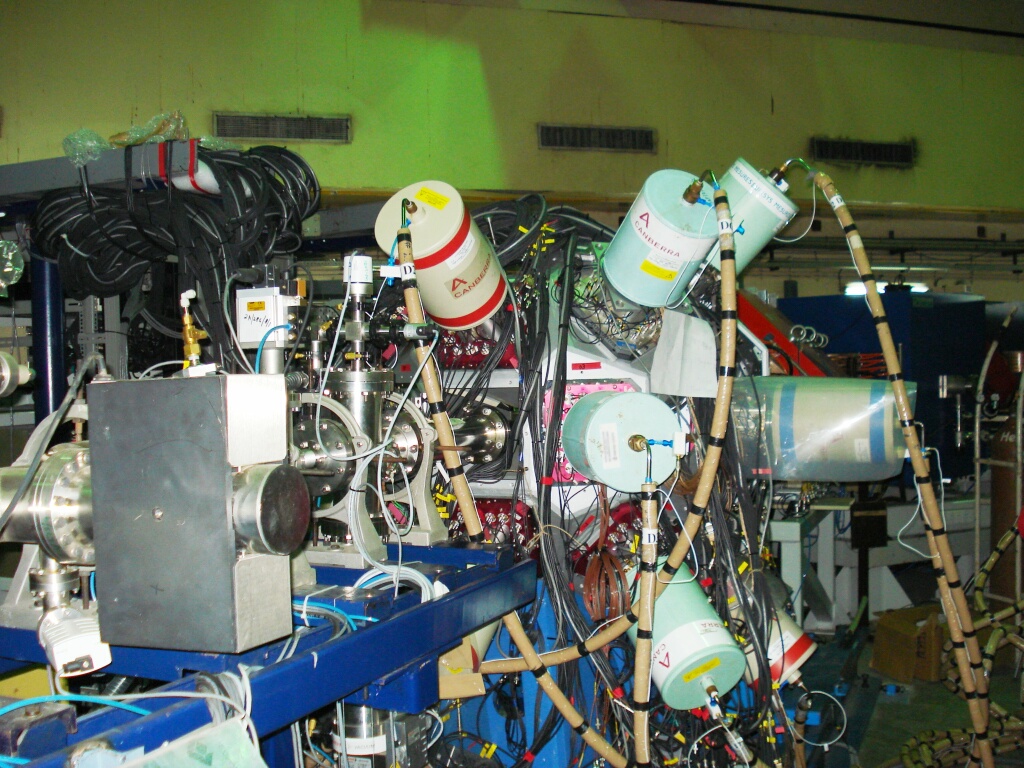

Fabrication of the mechanical support structure at IUAC for holding 24 Clover detectors was taken up in early 2007 and completed by mid-2007. It was decided that the first campaign with the full INGA during 2007-2008 would take place at IUAC. Installation of the mechanical structure, cabling and electronic modules started by August 2007. The detectors and shields from all the collaborating institutions were received by January 2008. The first facility test to optimize the transport of beam at INGA beam line was carried out in February 2008. During March to June, 2008, the first cycle of experiments with the INGA facility was carried out.

Features

Technical Details

- INGA is an array of Compton-supressed Clover detectors with nearly 4π geometric coverage.

- Individual shields subtend ∼ 30o at the target.

- Maximum of 24 Clover detectors can be accommodated in the array.

- Total photopeak efficiency of INGA is ∼ 5%.

- The array is optimized for γ-γ-γ and higher fold data.

- INGA can be used with auxiliary detectors like CsI-based charge particle detector array.

Beamline

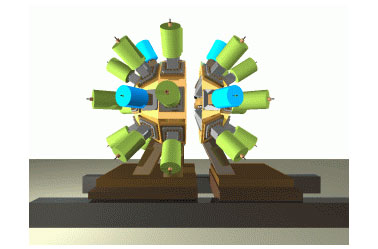

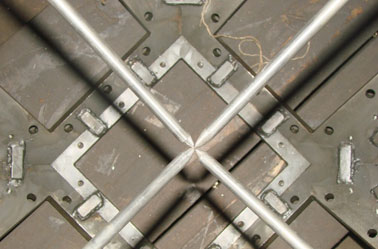

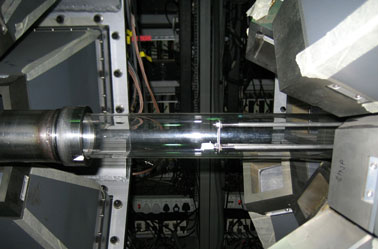

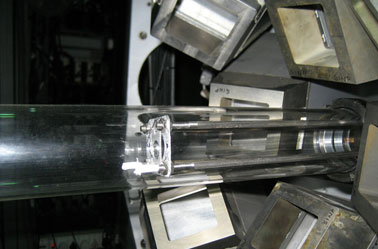

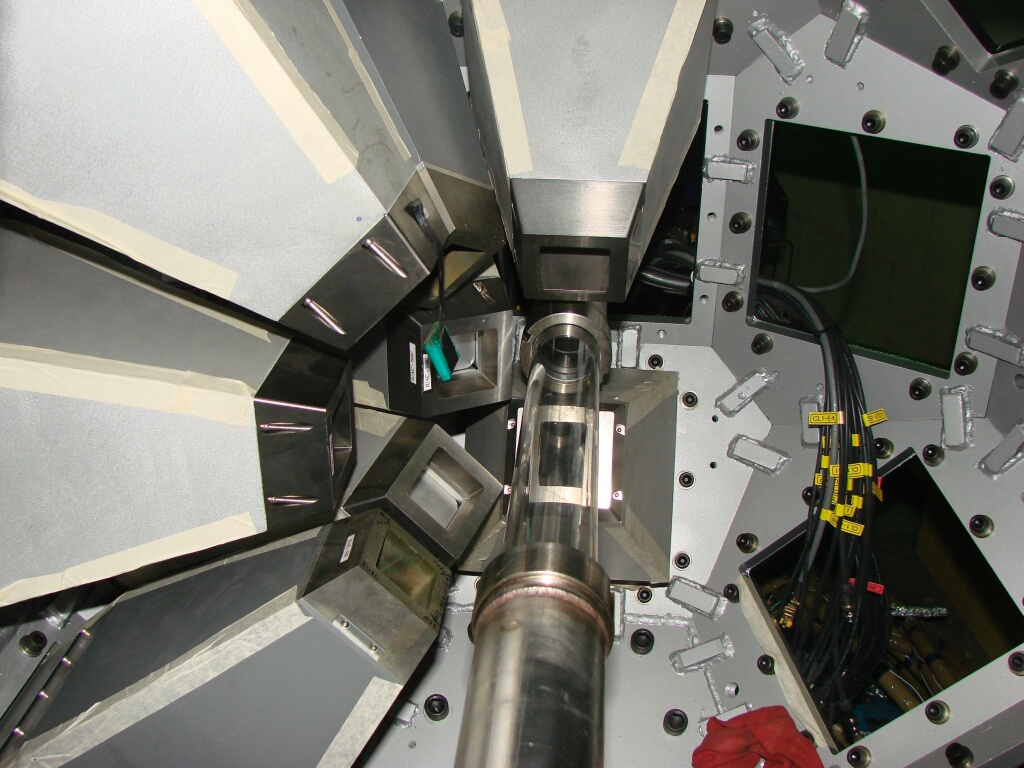

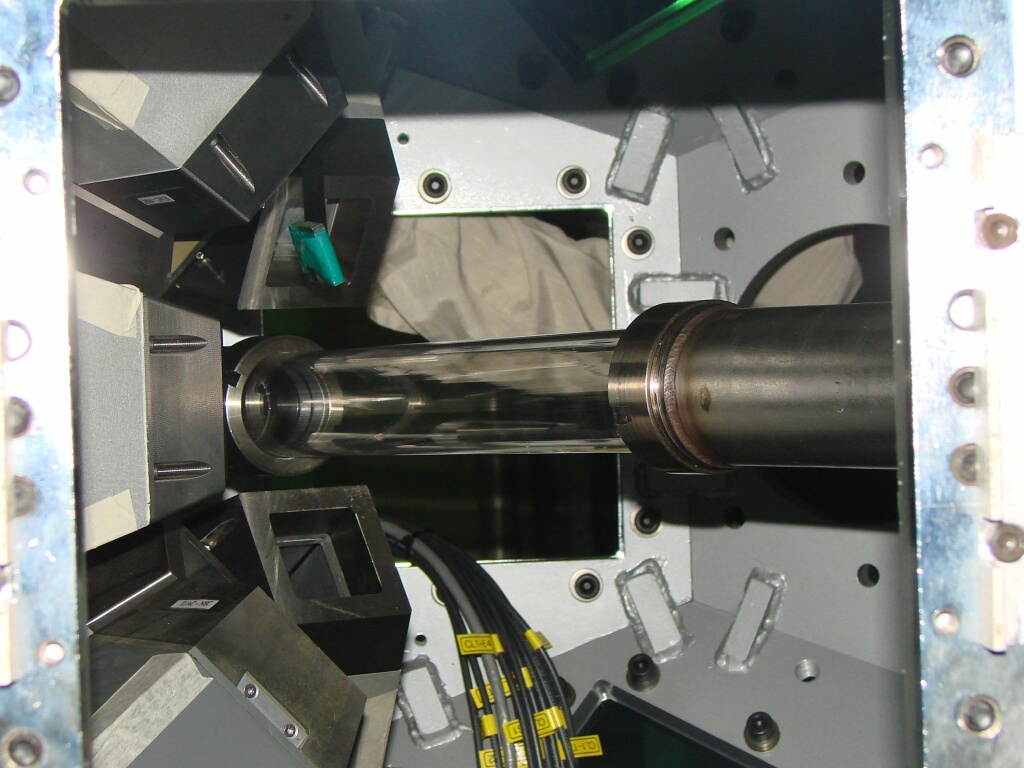

One of the major challenges in designing the beam line was the small clearance of ∼ 7.5 cm along beam axis between the collimators of the anti-Compton shields. A stainless steel beam tube of 6 cm diameter (top-left figure) has been used inside the array. The backward array can slide back on its guide rails without disturbing the beam line. The scattering chamber is made of 2″ diameter glass tube to minimize the attenuation of γ-rays in the chamber walls. Wilson seal couplings are used between the scattering chamber and beam tubes at both ends. The target is mounted on four rods inserted along the beam tube. The beam tube downstream of the target is mounted rigidly on the mechanical structure of the forward array.

Outside the array, 4″ diameter stainless steel tubes are used for transporting the beam. A Turbo-molecular pumping system backed by a rotary pump, with dedicated home-made control unit has been installed in the beam line. A removable collimator of 5 mm diameter with current readout is put at 1.5 m upstream of the target. In actual operation, the current intercepted by this collimator is minimized for centering the beam on target.

Infrastructure

Automatic LN2 Filling System

A dedicated home-made controller with embedded PC has been developed to provide an automatic liquid nitrogen filling system (LN2) for the Clover detectors. The supply of LN2 is from a 1000 l dewar (INOX make) which can be periodically (once in 2 days) filled from a larger dewar (20,000 l), kept outside the beam hall. The distribution of LN2 is done with a four-column manifold catering to sixteen detectors of backward array and another two-column manifold catering to eight detectors of forward array.

Electrically operated cryogenic valves of Jefferson make (1/2″ diameter, normally closed), are employed for controlling the flow of LN2 to the detectors. These can be operated under software control by the program linserv working in linux operating system. The temperatures at the overflow ports of the Clover detectors and the filling manifolds are measured using platinum resistance thermometers (PT100) and the valves are closed under overfill condition. A graphical user interface (named, fill) enables the user to monitor the filling status of individual detectors. The detectors are filled automatically twice a day.

Power and Signal Cabling

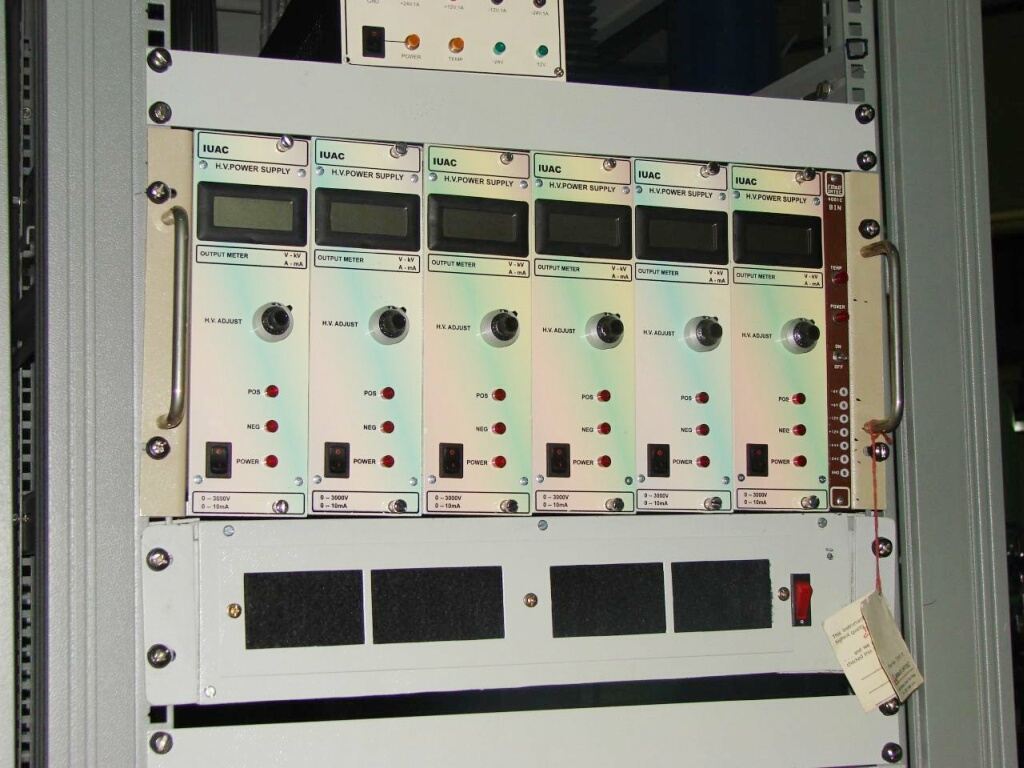

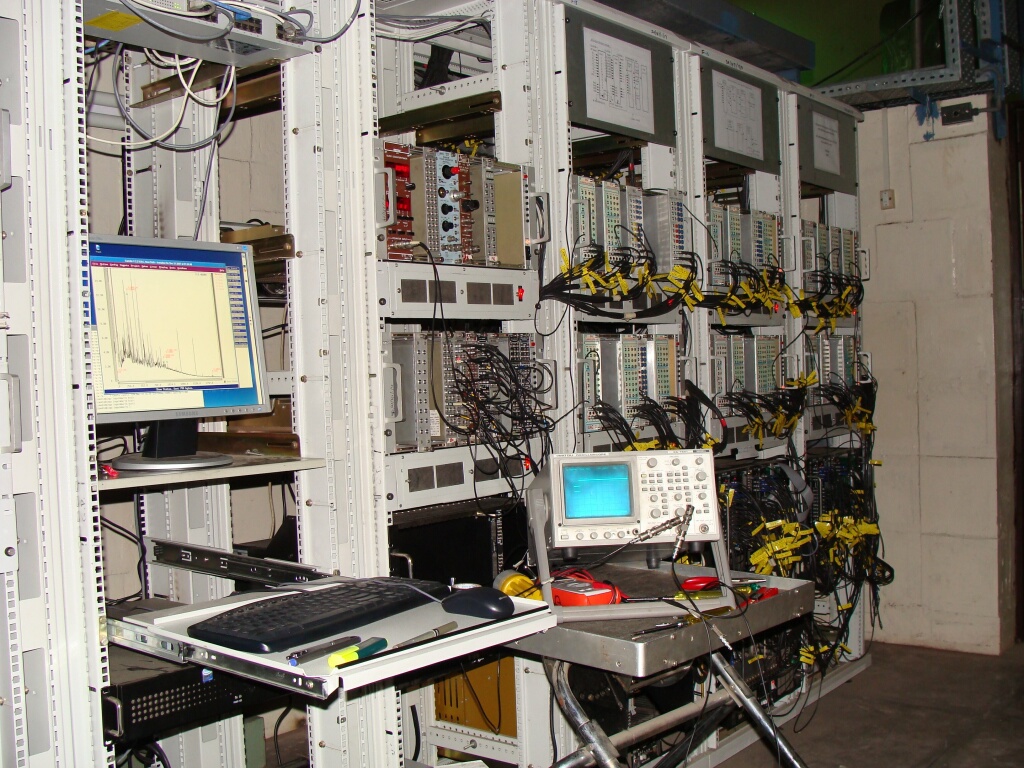

The electronics for the various subsystems for INGA are mounted on 19″ instrumentation racks powered by UPS with surge protection circuitry. Two racks are used for mounting the LN2 control valves and two for housing the high voltage supplies for Clover detectors and anti-Compton shields. The energy and timing signals from the detectors are taken to the electronics cabin using RG58 signal cables. The cable ends in the electronics cabin are grouped into three patch panels. RG172 cables are used for the interconnection between the patch panels and the electronic modules.

Electronics and Data Acquisition System

NIM and CAMAC modules developed in-house

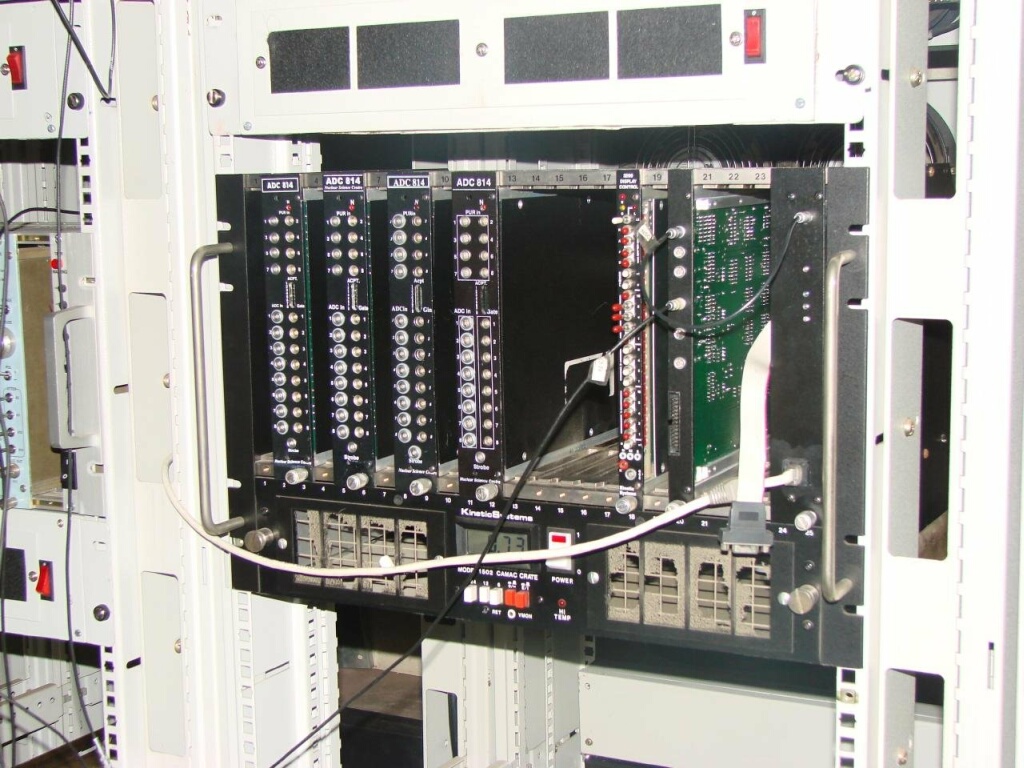

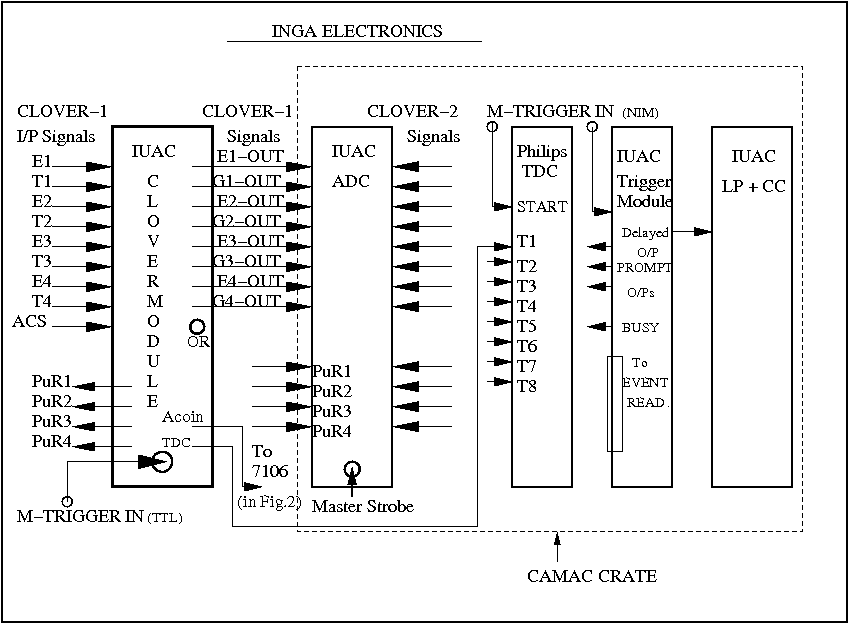

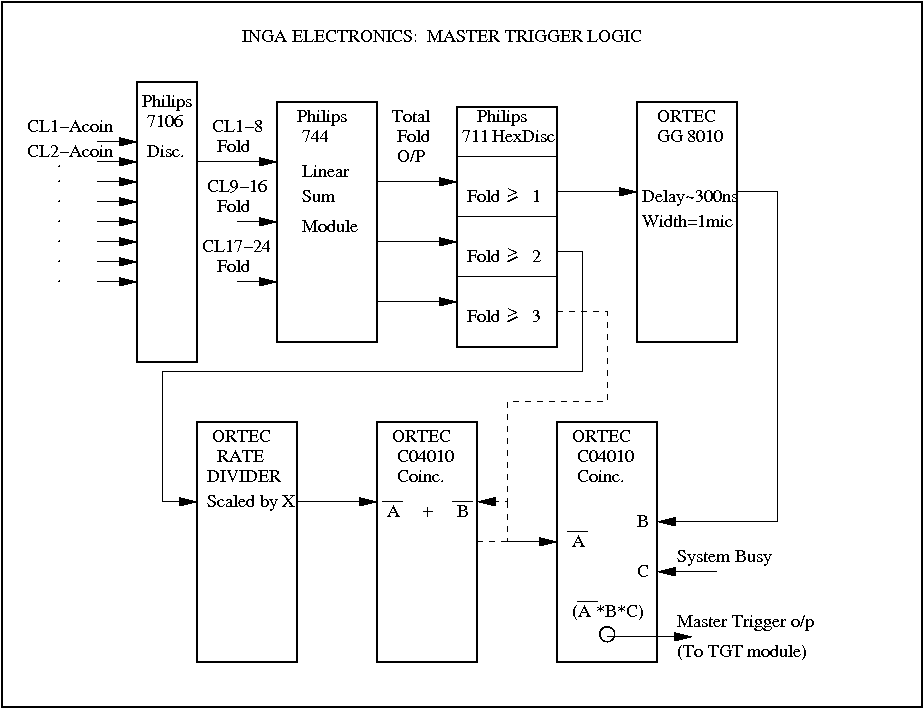

Home-made Clover modules are used for processing the energy signals from Clover detectors and anti-Compton shields. The timing logic for Compton-suppression along with the generation of required strobes for data collection and pile-up rejection were also incorporated in this module. The gain setting of the shaping amplifiers of Clover segments are kept at 4 MeV range. One NIM bin is used for powering four Clover modules. Eight detectors are grouped into one unit for creating multiplicity of γ-rays and for collecting data through one CAMAC crate. The combined multiplicity from all three crates is used for event selection.

New home-made LPCC CAMAC modules have been fabricated combining the List Processor (LP) and the Crate Controller (CC) which enables the data collection rates up to 1700 kilo bytes per second. Three CAMAC crates each having four 14 bit, 8 channel home-made AD814 ADCs, are used to collect data from all Compton-suppressed Clover detectors. The first CAMAC crate has the trigger generator which entertains the event trigger and transmits it to the other two CAMAC crates via trigger receiver modules of respective crates to maintain the synchronization of data between the three crates. The TDCss (PHILLIPS 7186) are used to create the hardware bit pattern in each CAMAC crate. The hardware bit pattern based data collection (CNAF list changes as per the bits raised for each event in TDC's of each crate) is also enabled to have more data collection due to zero suppression in data readout. The data collection software CANDLE is run in a dedicated PC with local data archival system. All the bias supplies, analogue processing modules and analogue to digital converters (except TDCs) have been fabricated in-house.

Trigger Logic

Data Rates

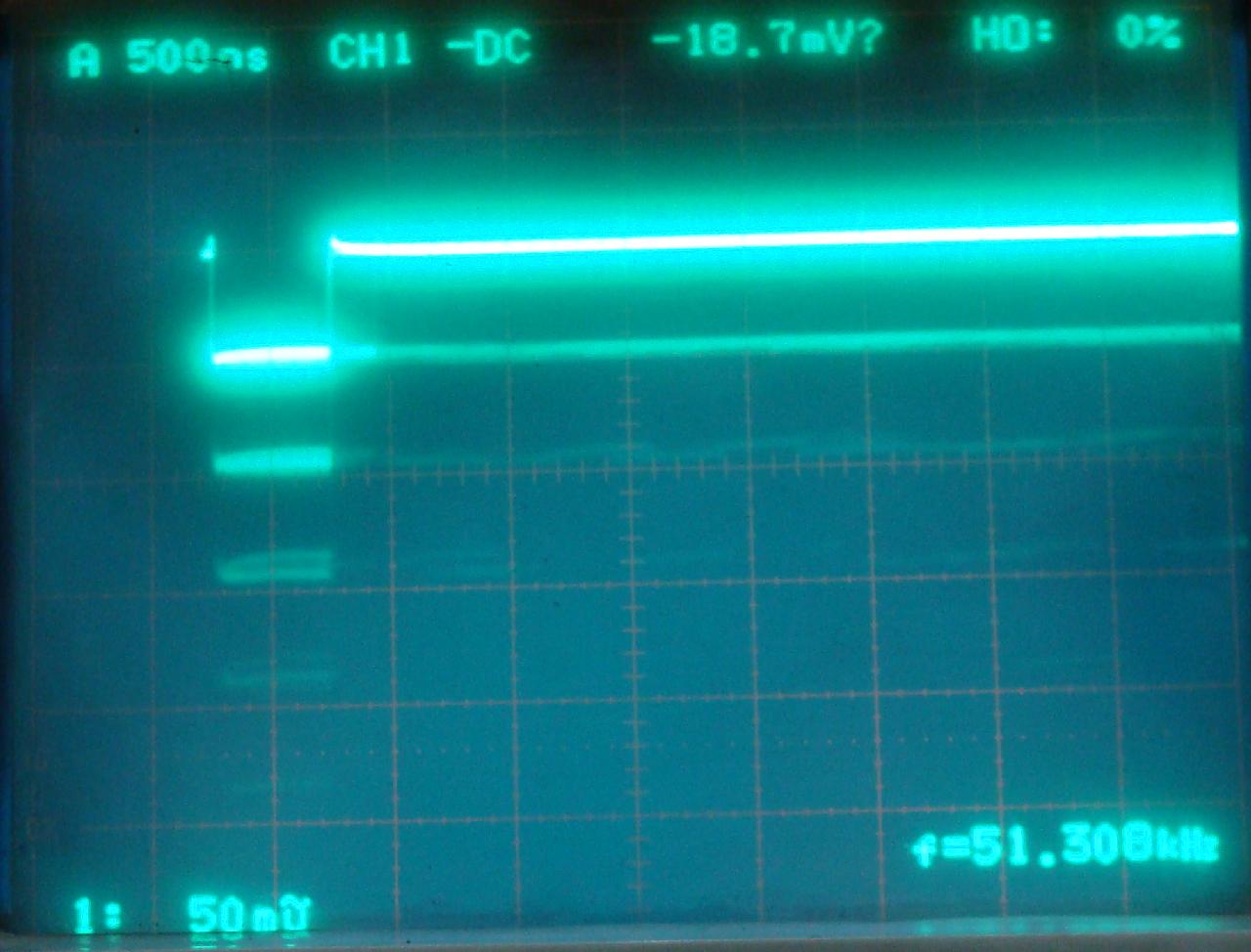

For multi-crate readout of ∼ 120 parameters, hardware supression is enabled, based on the hardware bit pattern readout of TDC. In the triples (γ-γ-γ) mode, on average the dead time is about 45 μs. Typical coincidence count rates were ∼ 12 kcs (γ-γ) doubles and 3-4 kcs (γ-γ-γ) triples for a total singles (γ) rate of 60-80 kcs. An oscilloscope trace of the multiplicity distribution is shown in the left figure.

People

Scientists:

Alumni

-

Pradip Datta (2001-2008)

Topic: High Spin Spectroscopy of Neutron Rich Nuclei in Mass-100 Region

Affiliation: Ananda Mohan College/ Saha Institute of Nuclear Physics Kolkata, India

Present Affiliation: Ananda Mohan College, Kolkata

-

Krishichayan (2002-2007)

Topic: Study of high spin states in nuclei around magic shell closure

Affiliation: UGC-DAE Consortium for Scientific Research/ University of Calcutta

Present Affiliation: Triangle Universities Nuclear Laboratory, Duke University, USA

-

Anagha Chakraborty (2002-2008)

Topic: Spectroscopy of Nearly Spherical Nuclei at Higher Angular Momentum

Affiliation: UGC-DAE Consortium for Scientific Research/ University of Calcutta

Present Affiliation: Department of Physics, Visva-Bharati, Santiniketan, West Bengal

-

Rajesh Thakur (2002-2008)

Topic: Study of Nuclear level structure at high excitation and angular momentum Via gamma-ray spectroscopy

Affiliation: Panjab University, Chandigarh

Present Affiliation: JCDAV College Dasuya, Hoshiarpur (Affiliated to PU)

-

Rajarshi Raut (2002-2009)

Topic: Nuclear Structure Studies in the Vicinity of N=82 Shell Closure

Affiliation: Saha Institute of Nuclear Physics (University of Calcutta)

Present Affiliation: UGC-DAE CSR, Kolkata Centre

-

Anukul Dhal (2002-2010)

Topic: Study of High Spin States in 139Pm, 137Pm and 78Kr : Role of Intruder Orbitals

Affiliation: Banaras Hindu University, Varanasi

Present Affiliation: ELI-NP, Romania

-

Rishi Kumar Sinha (2002-2012)

Topic: Nuclear Structure Studies of Exotic Nuclei

Affiliation: Banaras Hindu University, Varanasi

Present Affiliation: NIL

-

Tumpa Bhattacharjee (2004-2009)

Topic: Nuclear Structure Studies in La-Ce Region

Affiliation: Variable Energy Cyclotron Centre

Present Affiliation: Variable Energy Cyclotron Centre

-

Samarjit Sihotra (2004-2009)

Topic: Nuclear structure studies in A~100-130 mass region

Affiliation: Panjab University, Chandigarh

Present Affiliation: Panjab University, Chandigarh

-

Santosh Roy (2004-2013)

Topic: Interplay of collective and magnetic rotation in nuclei of mass 100 region

Affiliation: SNBNCBS/SINP West Bengal Univ. of Tech

Present Affiliation: Inter University Centre for Astronomy & Astrophysics, Pune

-

Tarkeshwar Trivedi (2005-2010)

Topic: Study of Spectroscopic Properties of Proton Rich Nuclei

Affiliation: University of Allahabad

Present Affiliation: Guru Ghasidas Vishwavidyalaya, Bilaspur

-

Dinesh Negi (2005-2011)

Topic: High spin spectroscopy of nuclei in the mass A~110 region

Affiliation: Jawaharlal Nehru University

Present Affiliation: Tata Institute of Fundamental Research, Colaba, Mumbai

-

Deepika Choudhury (2007-2012)

Topic: Search of New Coupling Schemes in Nuclei in 110 mass region

Affiliation: Indian Institute of Technology Roorkee

Present Affiliation: Indian Institute of Technology Ropar

-

Ritwika Chakrabarti (2007-2013)

Topic: Spectroscopic study of A~30 nuclei spanning the region from the valley of stability towards the island of inversion

Affiliation: UGC-DAE Consortium for Scientific Research/ University of Calcutta

Present Affiliation: Department of Physics, University of Mumbai

-

Surender Kumar (2008-2014)

Topic: Nuclear structure studies in vicinity of the z=50 shell closure through the fusion-evaporation reactions

Affiliation: Panjab University, Chandigarh

Present Affiliation: Govt. College, Bassa (Gohar) Distt. Mandi (H.P.)

-

Ritika Garg (2008-2015)

Topic: Nuclear Structure Studies in A = 135 Mass Region: Search for Magnetic Rotation Phenomenon

Affiliation: University of Delhi

Present Affiliation: University of Delhi

-

Navneet Kaur (2009-2016)

Topic: Nuclear structure studies in mass A=130region

Affiliation: Panjab University, Chandigarh

Present Affiliation: S.A. Jain College, Ambala City

-

S S Bhattacharjee (2010-2017)

Topic: Nuclear Structure studies of transitional nuclei

Affiliation: University of Calcutta

Present Affiliation: TRIUMF, Vancouver, Canada

-

Vipenpal Singh (2011-2017)

Topic: In-beam nuclear structure studies of some neutron deficient nuclei in 100 mass region

Affiliation: Panjab University, Chandigarh

Present Affiliation: Guru Nanak National College Doraha, Ludhiana Punjab

-

Siddarth Rai (2012-2019)

Topic: Nuclear Structure Studies in Mass Region A~60

Affiliation: Visva-Bharati, Santiniketan

Present Affiliation: Department of Physics, Salesian College, Siliguri

-

Kshetrimayum Rojeeta Devi (2012-2018)

Topic: High Spin Features of Nuclear Structure in Mass A=130 Region

Affiliation: University of Delhi

Present Affiliation: Inter-University Accelerator Centre, New Delhi

-

Saikat Chakraborty (2012-2019)

Topic: Collective and non-collective states in transitional nuclei

Affiliation: Banaras Hindu University, Varanasi

Present Affiliation: Inter-University Accelerator Centre, New Delhi

-

Pragati (2013-2018)

Topic: Gamma Spectroscopy of Trans-lead Nuclei

Affiliation: Indian Institute of Technology, Roorkee

Present Affiliation: Indian Institute of Technology, Roorkee

-

Shashi Shekher Tiwary (2013-2020)

Topic: In-beam γ-ray spectroscopy of transitional nuclei

Affiliation: Banaras Hindu University, Varanasi

Present Affiliation: Banaras Hindu University, Varanasi

-

S Gholam Wahid (2014-2020)

Topic: Novel Shapes and Symmetries in Heavy Nuclei

Affiliation: UM-DAE Center for Excellence in Basic Sciences, University of Mumbai

Present Affiliation: UM-DAE Center for Excellence in Basic Sciences, University of Mumbai

Scholars

-

M. Kumar Raju

Department of Nuclear Physics Andhra Uni., Visakhapatnam India

-

G. Jnaneshwari

Department of Nuclear Physics Andhra Uni., Visakhapatnam India

Publication

-

Systematics of antimagnetic rotation in even-even Cd isotopes,

Santosh Roy, S. Chattopadhyay, Pradip Datta,

S. Pal, S. Bhattacharya, R.K. Bhowmik, A. Goswami, H.C.

Jain, R. Kumar, S. Muralithar, D. Negi, R. Palit, R.P. Singh,

Phys. Lett. B 694 (2011) 322. -

Indian National Gamma Array at IUAC

S. Bhowal, C. Lahiri, R. Raut, P. Singh, M.K. Raju, A. Goswami, A.K.

Singh, S. Bhattacharya, T. Bhattacharjee, G. Mukherjee,

S. Bhattacharyya, S. Muralithar, R.K. Bhowmik, N. Madhavan,

R.P. Singh, G. Gangopadhyay, J.Phys.(London) G 38 (2011) 035105.

Contact us

Dr. S. Muralithar

Inter University Accelerator Centre Aruna Asaf Ali Marg, Post Box 10502 New Delhi 110067, India